Bryant Air Conditioners Error Codes

Bryant Air Conditioners Error Codes

Bryant Ac Maintenance Dubai

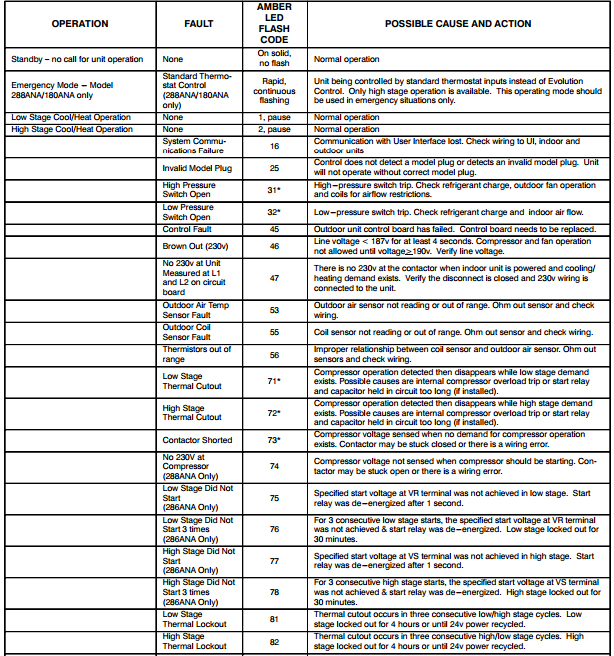

Table 19 shows the status codes flashed by the amber status light.Most system problems can be diagnosed by reading the status code as flashed by the amber status light on the control board.

The codes are flashed by a series of short and long flashes of the status light. The short flashes indicate the first digit in the status code, followed by long flashes indicating the second digit of the error code.

A NOTE ABOUT SAFETY Any time you see this symbol in manuals, instructions and on the unit, be aware of the potential for personal injury. There are three levels of precaution: DANGER identifies the most serious hazards which will result in severe personal injury or death. WARNING signifies hazards that could result in personal injury or death. CAUTION is used to identify unsafe practices which would result in minor personal injury or product and property damage. NOTE is used to highlight suggestions which will result in enhanced installation, reliability, or operation.

PERSONAL INJURY, DEATH AND / OR PROPERTY DAMAGE HAZARD Failure to follow this warning could result in personal injury, death or property damage. Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion, fire, electrical shock, or other conditions which may cause personal injury or property damage. Consult a qualified installer, service agency, or your distributor or branch for information or assistance. The qualified installer or service agency must use factory–authorized kits or accessories when modifying this product. Read and follow all instructions and warnings, including labels shipped with or attached to unit before operating your new air conditioner.

ELECTRICAL SHOCK HAZARD Failure to follow this warning could result in personal injury or death. Disconnect all electrical power to the indoor air handler or furnace before removing access panels to perform any maintenance. Disconnect power to both the indoor and outdoor units.

Bryant Air Conditioners Heat Pumps Troubleshooting Dubai

Fault: System Communications Failure

Possible Cause And Action: Communication with User Interface lost. Check wiring to User Interface, indoor and outdoor units

Fault: Invalid Model Plug

Possible Cause And Action: Control does not detect a model plug or detects an invalid model plug. Unit will not operate without correct model plug

Fault: High Pressure Switch Open

Possible Cause And Action: High —pressure switch trip. Check refrigerant charge, outdoor fan operation and coils for airflow restrictions

Fault: Low Pressure Switch or Discharge Temp Switch Open

Possible Cause And Action: Low -pressure switch or discharge temperature switch trip. Check refrigerant charge and indoor air flow.

Fault: Control Fault

Possible Cause And Action: Outdoor unit control board has failed. Control board needs to be replaced.

Fault: Outdoor Air Temp Sensor Fault

Possible Cause And Action: Outdoor air sensor not reading or out of range. Ohm out sensor and check wiring

Fault: Outdoor Coil Sensor Fault

Possible Cause And Action: Coil sensor not reading or out of range. Ohm out sensor and check wiring

Fault: Thermistors out of range

Possible Cause And Action: Improper relationship between coil sensor and outdoor air sensor. Ohm out sensors and check wiring

Fault: Low Stage Thermal Cutout

Possible Cause And Action: Compressor operation detected then disappears while low stage demand exists. Possible causes are internal compressor overload trip or start relay and capacitor held in circuit too long

Fault: High Stage Thermal Cutout

Possible Cause And Action: Compressor operation detected then disappears while high stage demand exists. Possible causes are internal compressor overload trip or start relay and capacitor held in circuit too long

Fault: Low Stage Thermal Lockout

Possible Cause And Action: Thermal cutout occurs in three consecutive low/high stage cycles. Low stage locked out for 4 hours or until 24v power recycled.

Recent Comments